Knowledge center

How to Upload and Process Your 3D Model

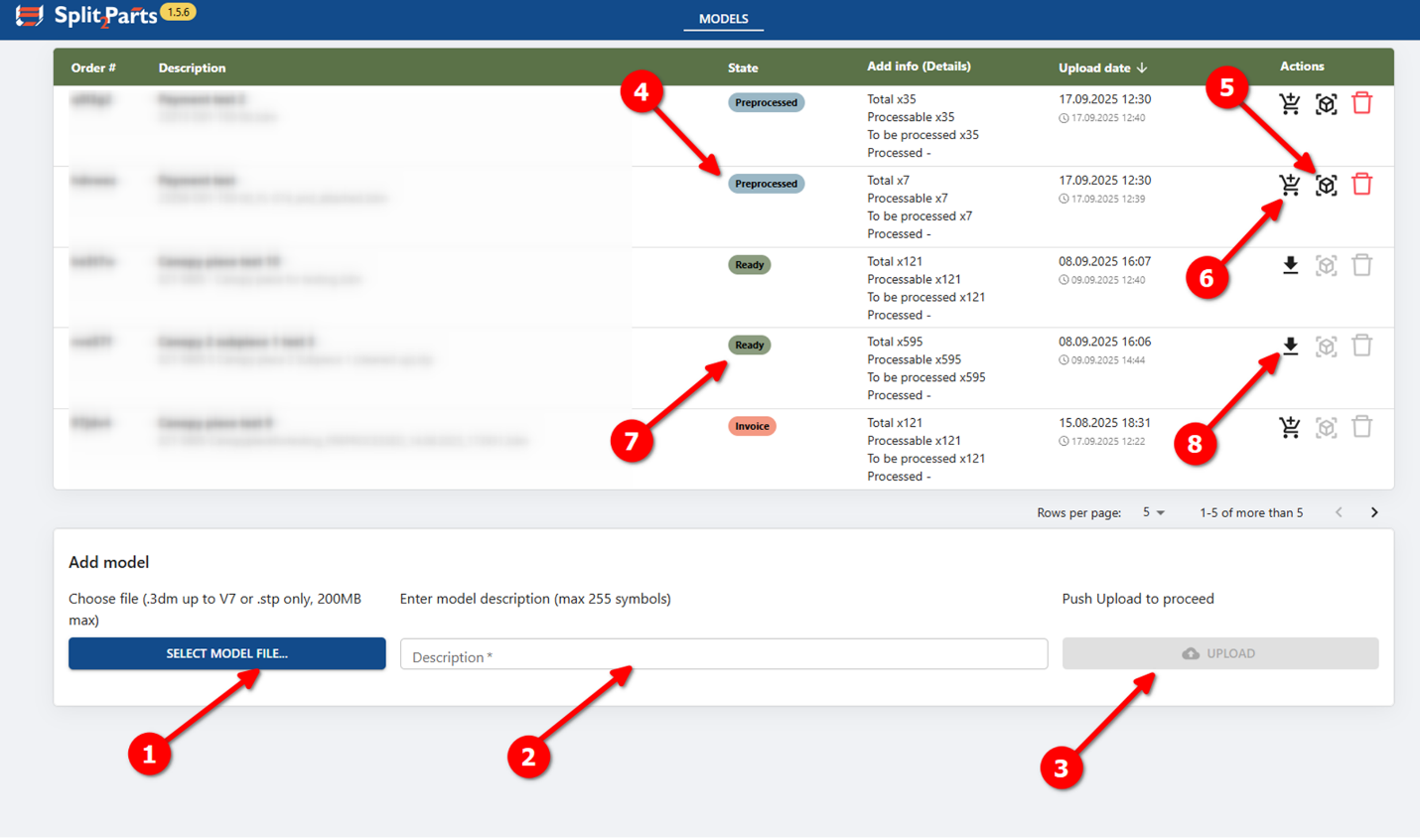

- Prepare your file

Select a file with your 3D model. The model must meet these requirements:- Supported formats: .step / .stp or .3dm (Rhino 7)

- Maximum file size: 60 MB

- Maximum number of objects: 200

- Public alpha limitation: only plate parts are supported

(flat or bent plates, no machining such as chamfers, bevels, blind holes) - Plate parts must be solid objects or closed polysurfaces

(other object types will be ignored) - Do not include profiles such as circular or rectangular tubes, flat bulbs - these may be detected as plates and processed incorrectly

- Add a description

Enter a short description of your model. - Upload the model

Click Upload.

After upload, the model automatically enters the Preprocessing stage, where it is checked and prepared.

During preprocessing:- If the model contains more than 200 objects, processing stops automatically

- All objects except solids and closed polysurfaces are removed

- Plate parts are detected, and their thickness is measured

- Wait for preprocessing

The model status will change to Preprocessed.

This may take from 5 minutes up to several hours, depending on model size and complexity. - Review the model (optional)

Once preprocessing is complete:- A 3D model view becomes available in your browser

- You can inspect the model and adjust part attributes if needed

(this step is optional)

- Purchase and start processing

When the model is ready:- Click Purchase

- Complete payment

(in public alpha, a fixed price applies)

- Wait for processing

Model processing can take 30 minutes up to 24 hours, depending on complexity.

When finished, the model status will change to Ready. - Download results

When the status is Ready:- The Purchase button is replaced by Download Contours

- Click it to download a ZIP package containing:

- .DXF contours, sorted by material and thickness

- .STP files for individual parts, also sorted by material and thickness

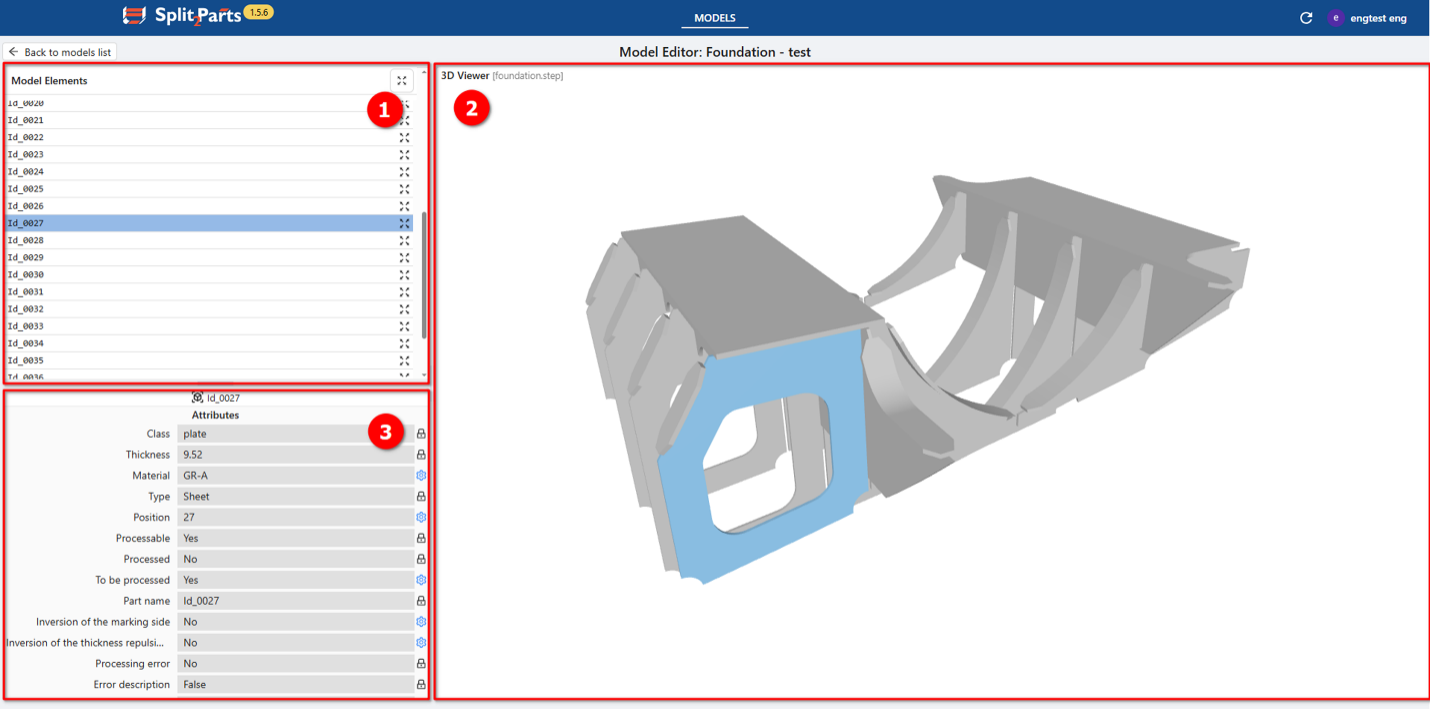

3D viewer window layout:

3D Viewer Layout

The viewer consists of three main areas:

- Model Elements List

- Shows all detected parts

- Click a part to:

- highlight it in the 3D view

- display its attributes

- 3D Viewer

- Displays the cleaned-up 3D model

(invalid objects such as lines or non-solids are removed) - You can rotate, zoom, and pan the model

- Clicking a part highlights it and shows its attributes

- Displays the cleaned-up 3D model

- Attributes Panel

Shows attributes of the selected part.- Editable attributes → marked with a blue gear icon

- Read-only attributes → marked with a grey lock icon

Part Attributes (Key Parameters)

- Class (read-only)

Part category (plate, profile, machined part, cast part, etc.) - Thickness (read-only)

Plate thickness (defined automatically during preprocessing) - Material (editable)

Default is GR-A, can be changed manually (text input) - Type (read-only)

Part type (sheet, L-profile, HP, tube, etc.) - Position (editable)

Position number shown near marking lines on connected parts - Processable (read-only)

Indicates whether the part can be processed - Processed (read-only)

Shows whether the part has already been processed

(always No in the 3D viewer) - To be processed (editable)

Controls whether the part will be processed (Yes/No) - Part name (read-only)

System-generated ID + original object name (if available) - Invert marking side (editable)

Use markings from another side of a plate

Note: in public alpha, contours are generated for both sides - Invert thickness repulsion side (editable)

Controls which side of the plate leaves marking lines

Note: in public alpha, mould side preview is not available

Current Limitations (Public Alpha):

Only plate parts are processed correctly.

A valid plate part must:

- be a solid or closed polysurface

- be flat or bent with straight edges (without chamfers, bevels)

- have no blind or stepped holes, other machining

- be symmetric relative to the neutral surface

- have side surfaces connected tangentially

Parts that do not meet these requirements may be processed incorrectly.